| Contact |

| Back | Next | Home |

Electrical

Machines

History

[This page is under construction!]

|

|

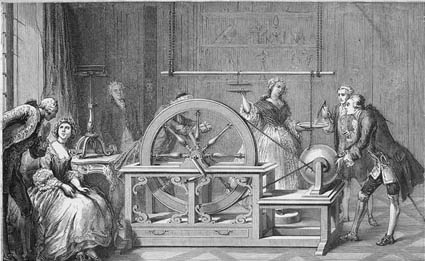

Otto von Guericke conceived the idea of making a machine of a ball of sulphur cast on an axle, and which was turned by a winch. This ball, when rapidly rotated, was rubbed by another person with the palms of his hands and the friction produced a strong electric charge on the sulphur. The experimenter then lifted the sphere by its spindle to use it for his experiments (see fig. 1). later it was found that a chain could be hung over the globe to receive the charge from the sulphur ball, and Sir Isaac Newton suggested the substitution of a glass globe.

In 1740 von Bose, a professor of physics at Wittemberg, substituted glass for the sulphur, and improved the rotating mechanism. He also suspended a metal cylinder above the globe by silk strings, with a metallic chain to conduct the electricity from the globe to the cylinder. This method of collecting is shown in Figure 2. This form of machine is credited to the Abbe Nollet in the middle of the 18th century, but is simply a modification of the Bose machine.

Fig. 2:

“Nollet” glass-globe style electrical machine

From that time the electrical machine evolved rapidly. First, the shape of the rubbed body was modified: Watson employed four glass globes; Wilson, Cavallo, and Nairne used cylinders instead of spheres, Sigaud de la Fond, Le Roy, Cuthbertson, Van Marum, and Ramsden, used plates of glass instead of cylinders or globes. This allowed a larger surface area to be rubbed, and increased the speed of rotation.

Another improvement, suggested by Winckler of Erfurt, consisted of using cushions of wool or leather, covered with tinfoil, or with an amalgam of tin or zinc. Typically either an amalgam of zinc, tin and mercury was employed, or else mosaic gold (sulphide of tin) was used, which was laid on with a very small portion of fat or wax. The friction then occurs between the amalgam and the glass.

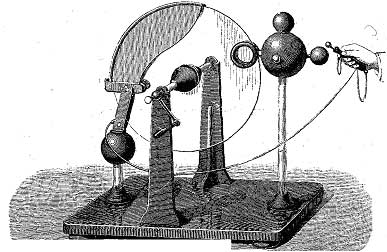

Fig. 3: The metal comb, utilizing Franklin’s “power of points”

In the early machines the electricity passed to the conductors as sparks, chains, or by strips joining the conductor to the insulated glass globes of the machine. In 1747 Franklin described his theory of the “power of points” where a pointed electrode was very effective at drawing the “electrical fire” at a distance. Wilson was the first to use points in the way that Franklin had just discovered. The prime conductor of his machine was a metal cylinder terminated in knobs and held by silk strings. A metal rod projected downwards from the conductor to the glass cylinder, and held a metal comb towards it (see fig. 3).

Friction Machines

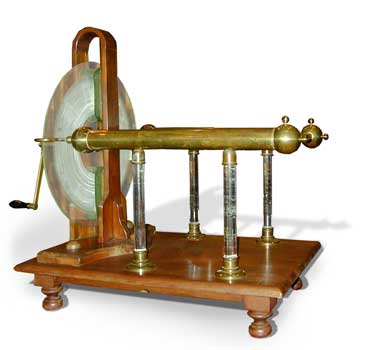

One of the earliest and certainly classic friction machines is the Ramsden machine, as shown in fig. 4.

Fig 4: Ramsden Friction Machine, circa 1786

Construction

A large circular plate of glass1 is mounted vertically on a metal axle, about

which it can easily be turned by a crank handle. When passing between the two wooden supports, the surface

of the glass is rubbed by two pairs of pads fixed to the supports. The

rotation of the glass then causes it to become electrified positively on

both faces. The negative charge of the pads is neutralized by being

connected to the ground through the frame, which is not insulated. Each

pad is stuffed with hair, and is covered with leather: Its surface is

coated with mosaic gold, or an amalgam of mercury with zinc,

bismuth, or tin. Attached to the pads

are silk cases which enclose the glass plate nearly as far as the combs,

these are to prevent loss of charge.

Once the electrical differential has been produced by the action of the pads on the glass, the charge must be collected in some way. Most friction machines do this via prime-conductors. They consist of two long brass cylinders terminated at each end by knobs, and insulated by glass legs. These cylinders are connected to one another (at the opposite end from the plate) by a metal rod. The ends of the conductors nearest the machine carry metallic combs bent round and brought with the points close to both faces of the glass plate, but not quite touching it (Franklin's points).

Operation

When the handle of the machine is turned the glass plate is

charged positively by friction against the pads; while in this state it

acts by influence (inductance) on the conductors, repelling a positive charge to the ends

of the conductors, and leaving the parts nearest to it, the combs,

negative.

The negative charge sets up an "electric wind" at the points of the combs, producing a continual discharge between the surface of the glass and the prime-conductors. The glass is continually being re-electrified positively by friction with the pads, thus causing an accumulation of electricity on the conductor.

An electroscope may be placed on one of the conductors in order to show the increase of the charge of the electricity.

To insure the proper working of the machine it is always necessary to have the room warm and dry; the glass legs supporting the conductors should be well cleaned before use, and wiped with a warm piece of flannel with a little paraffin oil upon it.

Fig. 5: Winter's electric machine.

In 1772 Le Roy, a French physicist, constructed a glass plate machine with only one pair of pads; he had, however, two insulated cylindrical conductors placed horizontally at opposite ends of a diameter, one attached to the pads and the other to the metallic comb, thus he collected both kinds of charge. Winter, an Austrian, slightly modified Le Roy's machine to a form shown in Fig. 5. The conductors are spheres; one is attached to the pads whilst the other is connected to 'the combs, constructed as two rings, one on each side of the glass. One conductor is charged positively, the other negatively. Winter's machine does not give a large quantity of electricity at each discharge, on account of the small size of the conductor, but it gives longer. sparks than the other forms of machine of the same size.

Nairne's machine (Fig. 6) is also arranged to give both kinds of charges. One of the conductors, attached to a comb, is charged positively as in the plate machine, while the other conductor attached to the pad is charged negatively. The machine uses a glass cylinder; it has a flap of silk attached to the pad passing over it to prevent loss. It is, however, found best not to collect both kinds of charge, but to join one of the conductors to the earth by a chain or wire.

Fig. 6: Nairne’s Electrical Machine

Van Marum2 designed an electric machine (Fig. 7), like either Ramsden's or Nairne's, capable of acting at will to collect either positive or negative charges, or both kinds at the same time.

Fig. 7: Van Marum Electrical Machine

If mercury is shaken up in a dry glass tube in the dark, a glow is seen, proving the production of small charges of electricity. In fact, enough electricity is produced to cause the tube to attract light bodies. This demonstrates that the friction of liquid bodies against solids can produce electricity.

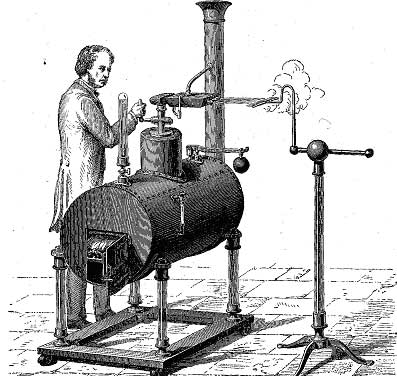

This method was not used, however, until, in 1840, an accident showed an easy method of producing large quantities of electricity by driving a jet of steam against a solid body. This is the principle of Armstrong's machine shown in Fig. 83. An insulated boiler is filled with distilled water, which produces high pressure steam that escapes through a row of jets after being partly condensed by passing through pipes surrounded by cold water. The drops of water produced by the condensation strike against a plate of box-wood round which the steam has to pass before it escapes from the jets made of the same wood, as shown in Fig. 9. Electricity is developed in proportion to the increase of the pressure of the steam; the jets become charged positively and the steam negatively. To collect the

Fig.

8: Armstrong's hydro-electric machine.

Fig. 9: steam Orifice

latter charge an insulated conductor is used, which is furnished with a series of points held opposite the jets. These hydro-electric machines are very powerful but were so difficult to use that they were never adopted in place of friction machines. There was one at the Polytechnic in London with forty-six jets, and which gave sparks two feet long, and one at the Sorbonne, in Paris, has eighty jets, and produced sparks several inches in length.

1Machines have been constructed with plates of sulphur. M. Richer has a note on this subject in the Comptes Rendus de l'Académie des Sciences, 1865. The choice of glass makes a difference. Electric instrument makers agreed that the old plate glass with natural vitrefied surface was the best. It is said that the superiority consists in there being so little potash used in its manufacture a the surfaces being, for that reason, less hydroscopic. Olive-coloured bottle glass, cobalt blue glass, and flint glass, are equally good for this purpose. Whatever is the nature of the plate, it is necessary to clean it at times with alcohol, naphtha, or paraffin oil, to remove any matter left from the Cushions.

2The same physicist made a machine celebrated in the history of the science ; it was shown among the Dutch historical. collection of apparatus at the International Electrical Exhibition at Paris in 1881. It was made by Van Marum in 1787, and was modified by Cuthbertson during the following years. Two discs 1'62 metres in diameter turned parallel between eight pairs of pads ; the metallic spheres terminating the conductors were thirty centimeters in diameter. Van Marum made some curious experiments with this machine, especially on sparks and brushes, which he obtained up to 60 centimeters (24 inches) in length.

3The discovery of the principles upon which this machine is constructed were made by chance. "A mechanic was busy repairing a steam-engine near Newcastle, having one hand in a jet of steam which was escaping from a leak, with the other hand on the lever of the safety valve ; he drew a brilliant spark and received a violent shock. Armstrong studied the. conditions of the phenomenon," &e. (Mascart's Traité d'Electricite statique).

| Contact |

| Back | Next | Home |